Choosing the right CAM software is crucial for dental labs aiming for efficient milling of crowns, bridges, dentures, and implants. This article objectively compares hyperDENT, MillBox, and SUM3D on key factors for dental users. Each section focuses on one aspect of the workflow, summarizing strengths and considerations for each platform.

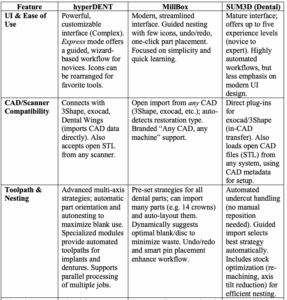

User Interface and Ease of Use

- hyperDENT: HyperDENT’s full version offers a highly flexible, customizable interface that appeals to experienced users. Its menus and settings are extensive, allowing advanced users to tailor workflows. However, it can be complex for beginners. In version 10, hyperDENT Express was introduced, where no deep CAM expertise is needed, making it fast for single-unit jobs.

- MillBox: MillBox was designed with ease-of-use in mind. Its modern interface drastically reduces on-screen clutter: secondary tools are tucked into collapsible menus and a guided workflow bar leads the user step-by-step. Industry reviewers note that MillBox is “extremely easy to use and very intuitive,” with one-click restoration placement (versus multiple clicks in older software) and undo/redo commands to recover from mistakes.

- SUM3D (Dental): SUM3D’s interface is mature but older in style. It emphasizes automation (automatically recognizing margins, insertion axes, etc.), but the UI has more buttons and levels which can overwhelm new users. It can be configured in up to five skill levels (novice to expert) to simplify the display for less experienced users.

Compatibility with CAD Systems and Scanners

- hyperDENT: HyperDENT provides built-in interfaces for major systems such as 3Shape, exocad, and Dental Wings. It can launch directly from 3Shape’s design software and import implant libraries and scanbody data from CAD. In practice, hyperDENT accepts standard open STL/CAM files from any CAD, so it works with scanned models from any intraoral scanner or design system.

- MillBox: MillBox is designed to accept designs from any dental CAD system – MillBox’s marketing lists “Any CAD, any machine, any material, any tool” as a key feature. In effect, this means MillBox can consume STL (or equivalent) outputs from 3Shape, exocad, Dental Wings, and other scanners without needing special format conversions.

- SUM3D (Dental): SUM3D also supports open data and direct CAD integration. It offers optional plugins that run inside exocad® and 3Shape®, enabling a one-click transfer from the CAD program to CAM. Even without plugins, SUM3D imports STL files from any CAD. It uses metadata from these files (including prep lines, insertion axes, etc.) to automate setup.

In summary, all three systems work with the popular CAD packages and scanner outputs; MillBox and SUM3D especially emphasize “open” compatibility, while hyperDENT provides specific connectors for 3Shape and exocad.

Toolpath Generation and Nesting Efficiency

- hyperDENT: hyperDENT offers advanced multi-axis toolpath strategies and extensive automation. For standard cases, it can automatically orient and nest parts in the blank to maximize material use. Its Auto-nesting feature places parts optimally as soon as the blank is selected, and a “local nesting” tool helps fine-tune positions. HyperDENT includes specialized modules (Implant, Denture, etc.) with pre-configured toolpaths: notably, it was “one of the first CAM systems to provide automated tool paths” for full dentures, allowing production of denture teeth or pre-milled sockets with minimal user input. In general, hyperDENT’s toolpaths are known for high precision surface finish, and it can simultaneously process multiple projects (running parallel CAM calculations) to boost throughput.

- MillBox: MillBox is built on the proven SUM3D engine but with user-friendly automation. It supports all common part types (crowns, copings, implant bars, etc.) with preset strategies. MillBox can import many parts at once (up to 14 files) and then auto-arrange them in the chosen blank. It even suggests the best blank (disc or block) to minimize waste: for example, it “will try to suggest the disc with the least amount of space remaining” that fits all restorations. MillBox also automates features like pin placement and margin detection. The 64-bit engine and constant updates have made its calculation speed very fast (users report that large arch cases now process much quicker than in older CAMs). In short, MillBox provides intuitive nesting tools, undo/redo, and intelligent blank management to make batch processing efficient.

- SUM3D (Dental): SUM3D was one of the first open CAMs for dental, so it has many dental-optimized toolpath features. It automatically detects undercuts and orients parts to eliminate manual repositioning. In fact, SUM3D advertises “no manual selection of curves needed” to identify milling areas, and no manual setup of holes – the system figures these out during import. It also offers advanced stock optimization: for example, it can re-machine partially used blanks, adjust axis tilt to reduce blank height, and apply autonaesting for material saving. Compared to MillBox, SUM3D does not have the newest GUI enhancements, but under the hood the toolpath strategies are similar (and MillBox essentially incorporates all of SUM3D’s core algorithms).

In practice, all three systems generate high-quality toolpaths for crowns/bridges/dentures, but MillBox and hyperDENT place more emphasis on ease-of-use in the nesting step (guided workflows), whereas SUM3D is known for giving experts fine-grained control over every parameter.

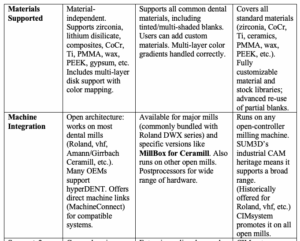

Material Support

- hyperDENT: Follow-Me emphasizes that hyperDENT is “material-independent”. It supports all common dental materials: zirconia, lithium disilicate, ceramics, composites, CoCr, titanium, PMMA/acrylic, wax, PEEK, gypsum, and more. hyperDENT also handles multi-layer or pre-shaded blocks: it carries the color gradient of multi-layer blanks into the CAM view so you can position the restoration at the desired shade.

- MillBox: MillBox likewise supports the full range of dental materials and lets users add new ones as needed. In practice, one clicks the material group (e.g. zirconia, PMMA, wax) and MillBox automatically chooses appropriate tools and speeds. The system also accounts for material properties (e.g. color zones in a multi-layer block) so that the final restoration uses the intended shade gradient.

- SUM3D (Dental): SUM3D explicitly lists a comprehensive material library. It can mill zirconia, CoCr, titanium, lithium disilicate, ceramics, PMMA, wax, PEEK, fiberglass, composite, gypsum, and even newer multilayer or pre-shaded materials. Users may load custom stock profiles for any blank shape.

All three CAMs allow simulation of the remaining material and can schedule secondary machining (like refacing a partially used disk) to maximize blank usage.

Integration with Milling Machines

- hyperDENT: hyperDENT is designed for “open architecture” CNC mills. It is compatible with virtually any dental milling machine that accepts external G-code or can be unlocked. In fact, Follow-Me partners with many mill manufacturers to create pre-tuned configurations. Additionally, hyperDENT offers MachineConnect, a direct interface for supported machines: it can launch jobs and even monitor machine status during CAM calculation. Overall, users report running hyperDENT on Roland, vhf, Hermle, Ceramill, and many other systems.

- MillBox: MillBox also runs on most open dental mills. It is often bundled by Roland for their DWX wet-milling systems, and there is a dedicated “MillBox for Amann Girrbach” edition for Ceramill Motion 2/3 mills. MillBox also works on Roland (DWX-4/42/52 etc.), Soricut, and other open controllers. In practice, any 4- or 5-axis mill that can load generic G-code can be used. Users of combined workflows (multiple brands of mills) may still operate multiple CAM seats, but MillBox’s flexible postprocessors and adapters cover a wide range of hardware.

- SUM3D (Dental): SUM3D, as CIMsystem’s legacy product, likewise targets any milling machine tool (even robots). Its industrial cousin is used on all kinds of machines, and the dental version comes in the same spirit. Historically, SUM3D has been sold for Roland, vhf, and many high-end mills. For SUM3D, the relevant takeaway is that it can be configured for any brand’s CAM post.

Essentially, all three CAMs are “open CAM” systems and support the common dental milling devices.

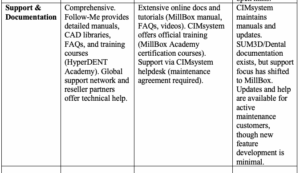

Customer Support and Documentation

- hyperDENT: Follow-Me (developer of hyperDENT) provides extensive support. Their website offers FAQs, technical documents, and CAD/CAM libraries for implant systems, as well as a contact form for technical support. They emphasize “premium support service” worldwide. Follow-Me runs training programs (often calledHyperDENT Academy) and webinars for different modules. In practice, large users (or equipment dealers) often receive on-site or online training, and updates are released periodically. The product manuals (F1-help context) are detailed, and users note that Follow-Me staff are responsive to support inquiries.

- MillBox: CIMsystem maintains a full support infrastructure for MillBox. There is an online MillBox Learning Center with user manuals, tutorials, FAQs and how-to articles. CIMsystem also sponsors the MillBox Academytraining (via third-party partners) offering certified courses for operators and experts. Technical support is provided through CIMsystem offices and distributors worldwide. However, as with many CAMs, ongoing support (for updates and direct help) usually requires a maintenance agreement. CIMsystem’s online “support” site explains that only current maintenance customers receive free technical support and updates.

- SUM3D (Dental): SUM3D support is handled by CIMsystem as well, but it has effectively been subsumed by MillBox. Documentation for SUM3D is available (old manuals, training videos) through CIMsystem, and customers with maintenance agreements can request help. In practical terms, many SUM3D users eventually migrate to MillBox and use its support channels. SUM3D’s documentation (from Apsom/CIMsystem) highlights ease-of-use and training-free operation, implying that heavy technical support is less needed, but advanced users may still access CIMsystem’s knowledge base for updates.

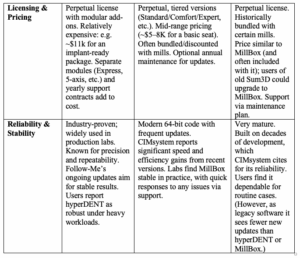

Licensing Model and Pricing

- hyperDENT: hyperDENT is sold as a perpetual license with modular editions. Follow-Me offers different bundles (Classic, Express, Implant, Denture, etc.) depending on needs. Pricing is relatively high. For example, a U.S. dealer lists a “hyperDENT Implant Light Bundle” at about $11,230. Additional modules (e.g. 5-axis, titanium milling, hybrid processing) add to the cost. Maintenance and updates are typically handled via an annual support contract. In general, hyperDENT tends to cost more than other basic CAMs due to its advanced features and professional focus.

- MillBox: MillBox is also perpetual-license software (with optional yearly maintenance). CIMsystem offers it in four versions (Standard, Comfort, Expert, etc.) to match lab size. Pricing is typically in the mid-range: anecdotal reports put MillBox (and its SUM3D predecessor) around $5,000–7,000 USD for a single-seat license. MillBox often comes bundled (and discounted) with mills like Roland’s DWX series. Because MillBox includes features that were once separate (e.g. from SUM3D), its sticker price can be higher than simpler packages, but dealers note it covers more material types and toolpaths out of the box.

- SUM3D (Dental): SUM3D’s licensing historically was similar: a perpetual license with upgrades via maintenance. When it was current, pricing was roughly in line with MillBox (especially since CIMsystem encouraged existing users to upgrade). A forum comment estimated Sum3D/MillBox licenses around $5–7K, compared to ~$7.5K+ for hyperDENT. Today, new users are typically directed to MillBox instead of SUM3D.

In all cases, CAM software pricing varies with included modules and mill compatibility, so exact costs are best obtained via dealer quotes.

Reliability and Stability

- hyperDENT: With years of development and a focus on high-end labs, hyperDENT is generally very stable in production environments. Follow-Me emphasizes proven precision and surface finish, and offers updates to ensure reliability. The ability to run multiple simultaneous CAM calculations on one workstation suggests confidence in stability. Anecdotally, users report that when properly configured, hyperDENT rarely crashes and delivers consistent results even on large (full-arch) cases.

- MillBox: MillBox’s modern 64-bit architecture and constant updates have improved reliability. CIMsystem has announced dozens of updates with hundreds of improvements in recent years. The Whipmix blog notes that MillBox “has become trusted by thousands of dental labs” and that since its introduction, it’s been updated to enhance speed and stability. In practice, many labs consider MillBox robust for daily use. Like any CAD/CAM, occasional software bugs have been reported, but the active user community and support network help address them.

- SUM3D (Dental): SUM3D’s strength is its long history. It evolved from CIMsystem’s industrial CAM tools and touts “the reliability of 30 years of software development experience”. This translates to a mature, debugged codebase. Sum3D in labs has been noted to run reliably on simple jobs; users often remark that its “powerful CAM” handles complex jobs well (albeit with a learning curve). However, since SUM3D is no longer actively developed for dental (beyond core maintenance), users may find fewer updates over time.

For most common tasks, all three CAMs yield reliable, repeatable outcomes when used correctly, but MillBox and hyperDENT have the advantage of ongoing feature and stability updates.

Summary Table

Sources

Product literature and expert commentary from Follow-Me (hyperDENT) and CIMsystem (MillBox/SUM3D). User and dealer reports are also cited where noted. All information reflects current capabilities and is intended to guide dental labs in evaluating these CAM solutions.

References

- “CAM Software Comparison.” Dental Lab Network, https://dentallabnetwork.com/forums/threads/cam-software-comparison.27444/.

- “Do You Offer MillBox Training?” CIMsystem Help Pages, https://help.cimsystem.com/docs/do-you-offer-millbox-training.

- “FOLLOW-ME! hyperDENT®.” Proto3000 Dental, https://dental.proto3000.com/dental/software-2/follow-me-hyperdent/.

- “FOLLOW-ME! Technology Group – hyperDENT.” FOLLOW-ME!, https://www.follow-me-tech.com/hyperdent/.

- “Help Pages.” CIMsystem, https://help.cimsystem.com/.

- “Hyper Dent Function Overview.” Unique Dental Supply Inc., https://udscanada.com/pages/hyper-dent-function-overview.

- “Introducing MillBox – A New Powerful CAM Interface Powered by SUM3D Dental.” Whipmix, https://whipmix.com/introducing-millbox-a-new-powerful-cam-interface-powered-by-sum3d-dental/.

- “Map with Drop Shadow – Hyperdent.” Dentcore, https://dentcore.com/pages/hyperdent.

- “MillBox.” CIMsystem Dental, https://www.cimsystem.com/dental/products/millbox/.

- “MillBox Features.” CIMsystem Dental, https://www.cimsystem.com/dental/products/millbox-features/.

- “MillBox for Amann Girrbach.” Amann Girrbach North America, https://www.amanngirrbach.com/en-us/software/millbox-for-amann-girrbach/.

- “Online Support – CIMsystem Dental.” CIMsystem, https://old.cimsystem.com/dental/online-support/.

- “Prices of CAM Software.” Dental Lab Network, https://dentallabnetwork.com/forums/threads/prices-of-cam-software.28364/.

- “Product Brochure V10.” FOLLOW-ME! Technology Group, https://www.follow-me-tech.com/wp-content/uploads/product_brochure_V10_en.pdf.

- “SUM3D – CIMsystem Industrial.” CIMsystem, https://www.cimsystem.com/industrial/products/sum3d/.

- “The Differences Between Sum3D and MillBox.” Whipmix, https://info.whipmix.com/the-differences-between-sum3d-and-millbox.

“SUM3D Dental Brochure.” APSOM Technologies, https://www.apsom.com/upload/pdf/Brochure_SUM3D_Dental_ENG_2016_LR.pdf

Comments