A recent study suggests that as the cone angle of the implant superstructure connection increases, the extraction torque of our fixing screw decreases proportionally, i.e., the larger the connection angle, the less loosening of the screw under load was smaller.

The management of screw loosening is a common issue in clinical practice. The changes in the torque are affected by the continuous, periodical repeating loads. The transmission of forces and stress distribution is influenced by numerous factors, such as occlusion, the quantity, and quality of the bone, implant body design, number and location of implants, implant inclination, osseointegration, abutment design, fit, and the micro-movements of the abutment, implant platform, thread design at the implant neck and implant-abutment connection, which may be external (EC) or internal (IC)

The height of the implant and superstructure may change as a result of the load. In this case, the occlusal height also decreases, thereby changing the occlusion, which leads to further biological (malocclusion, traumatic occlusal forces, peri-implant bone loss, temporomandibular dysfunction) and mechanical (screw loosening, fracture, superstructure deformation, fracture) issues.

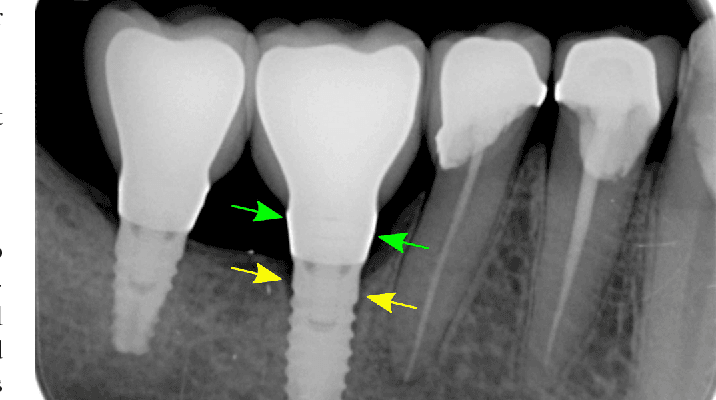

Many studies showed that implant geometry, bone quality, and site of implant placement affect load transmission mechanisms, thereby, subsequently, also affecting peri-implant bone resorption. Many studies showed that implant geometry, bone quality, and site of implant placement affect load transmission mechanisms, thereby, subsequently, also affecting peri-implant bone resorption.

The researchers of the study confirmed that the implant–abutment connection greatly influences the distribution of forces in different ways at different heights between the implant and the bone.

The mechanical stress was better distributed over the entire surface of the implant in the case of the 90-degree implant–abutment connection, compared to the 24-degree connection.

Regarding the 24-degree connection, the mechanical stress was greatest in the area where the cones meet, which represents the part of the implant with the smallest wall thickness; in addition, in the case of the 24-degree model, not only vertical but also horizontal deformation occurs. This horizontal deformation may lead to peri-implant bone resorption in the cortical bone.

When the taper angle is increased, more of the load is transferred to the implant wall than to the fixing screw. For this reason, the higher load on the smaller taper angle resulted in greater screw loosening, as more force is transmitted to the screw.

Conclusion

It can be concluded from the current analysis that, in the case of connections with a smaller taper angle, the masticatory forces acting on the implants were concentrated on the upper third of the implant body; this may result in horizontal deformation in the implant neck, which could lead to increased risk of cortical bone resorption.

While in the case of a larger taper angle, the masticatory force is evenly distributed over the body of the implant, this is also determined by a number of other factors, including the thread design, shape, length, and diameter of the implant. These results may contribute to the understanding of the long-term success of dental implants.

You can read the full article here : https://www.mdpi.com/1996-1944/16/5/1988

Comments