Due to the emerging number of new cases of coronavirus, the supply of personal protective equipments is running low. To overcome this, people are coming up with creative ideas to fill the gap.

Dr. Cody Boseman at Cottonwood Dental and his father, Dr. Jerald Boseman, who is working at the University of Utah school of dentistry came up with an innovative idea to combat the shortage of protective masks.

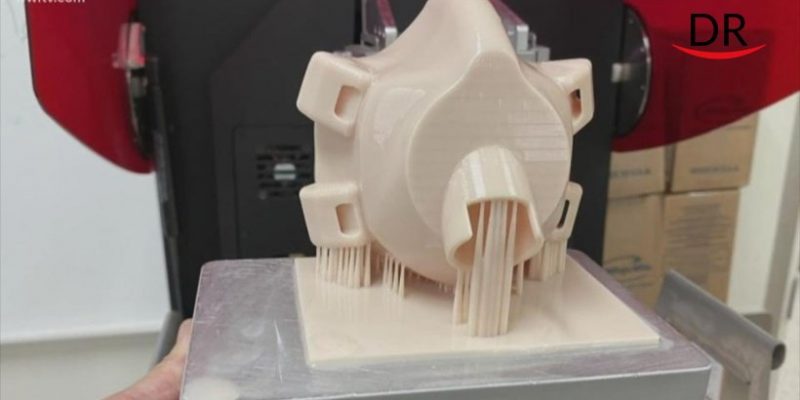

They usually used their 3D printers to make dental molds. As they can treat only emergency patients due to the pandemic, they decided to use this technology to make face masks instead.

An amazing thing about these masks is that they can be reused and the filters can be swapped out. These masks can be sterilized.

They got this idea from a couple of people who were doing similar things online.They finally settled on the design from a brain surgeon in Montana.

Until now they have made around 10-12 masks but they take quite a lot of time to make.Printing them alone takes four hour for one mask in Cody’s printer while two masks are printed in four hours in Jerald’s printer due to larger area.

Once the masks are printed, they are made to sit in alcohol bath for 10 minutes which is followed by curing in the light box to prevent them from being sticky. Then they have the rough patches filled off.

Then a filter is attached in in one of the two different ways, depending on the design. One is fastened with rubber bands and the other clips into place.

This is followed by customization of masks to the person that will be wearing it. They do it by using some dental material to seal up right around the space. A good seal is very important to get pure filtration as everybody’s face is a little different

The materials used to make each one comes out to about $5 to $6 per mask. These masks are printed using a resin, which is different from the 3D printers that use filament.

For now the Father-Son duo is customizing masks for their staff but once they figure out about mass production method, they will start donating them to anyone in need.

Cody said that have asked the company that makes his 3D printers to donate some resin for mask production but have not heard back yet.

The owner of Cottonwood Dentistry has urged to everyone who has 3D printers to start producing such masks for the people in need.

Comments